The pipe clamp collars are essential devices in hydraulic and pneumatic systems to secure and support pipes, ensuring safety and stability during operation. Their primary function is to reduce vibrations, prevent movement, and protect pipes from mechanical damage or premature wear. But how do they work, and what are their main applications? All useful information is included in this article. Let’s discover what pipe clamp collars are.

Function and structure of pipe clamp collars

Pipe clamp collars are designed to securely anchor pipes to a supporting structure, reducing the risks of unwanted movement and improving the system’s overall efficiency. Their structure typically includes two main components:

- The fixing bracket, made of metal, such as galvanized or stainless steel, which provides robustness and durability.

- The insert made of plastic or rubber material, which wraps around the pipe to protect it from vibrations and impacts.

These collars are available in various configurations, with a range of diameters and materials to suit different types of pipes and applications. Their ability to withstand extreme temperatures and harsh environmental conditions makes them ideal for use in industrial, agricultural, and automotive settings.

For a complete selection of pipe clamp collars, visit the pipe clamp collar section.

Types of pipe clamp collars

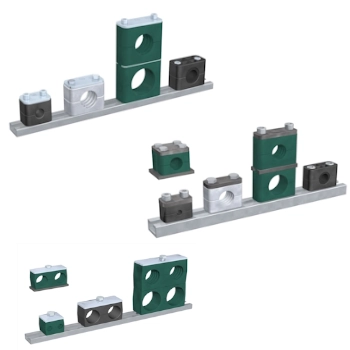

Pipe clamp collars differ in design, material, and application. Among the most common models are:

- Standard collars with one or two halves: used for general applications, providing simple and secure fastening.

- High-temperature collars: designed with heat-resistant materials for environments with exposure to high temperatures.

- Anti-vibration collars: equipped with rubber inserts or special materials to absorb vibrations and reduce noise.

- Multiple pipe collars: allow for the securing of multiple pipes together, optimizing space and improving system organization.

Each type is designed for specific operational needs and ensures optimal performance when correctly selected.

Applications of pipe clamp collars

Pipe clamp collars are used in a wide range of industries and applications, thanks to their versatility and reliability. In the manufacturing industry, for example, they are essential for securing hydraulic and pneumatic pipes within industrial machinery, ensuring stability and reducing wear caused by vibrations or movements.

In the agricultural sector, these devices are used to keep pipes in irrigation systems or machinery securely in place, ensuring continuous and trouble-free operation even in demanding working conditions.

In hydraulic and pneumatic systems, pipe clamp collars also play a key role by reducing vibrations and preventing structural damage, thereby improving the overall efficiency of pressure systems.

Furthermore, in the automotive sector, they are indispensable for securing pipes within vehicles, ensuring safety and stability even under continuous movement or high vibrations.

Thanks to their construction with high-quality materials, pipe clamp collars represent a reliable and adaptable solution for every operational context, becoming an essential element to enhance both the safety and efficiency of the systems in which they are used.