The clamps for pipes are essential components to ensure the stability and safety of a hydraulic or industrial system. Designed to securely support and fix pipes, clamps reduce vibrations, prevent the risk of damage, and contribute to maintaining the proper functioning of the entire system. When asked “clamps for pipes: which one to choose?” the answer depends on the specific needs of the system and operating conditions. Here is a useful guide to help you make your choices.

How many types of clamps are there?

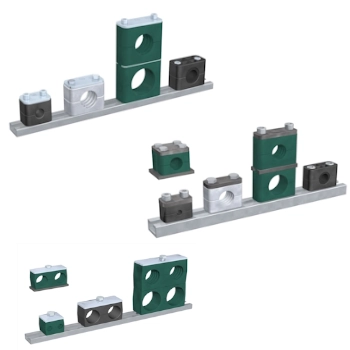

There are several types of these components, specifically three: plastic clamps, metal clamps, and anti-vibration clamps.

Plastic clamps

They are lightweight and corrosion-resistant, ideal for applications in humid or aggressive environments. They are often used in industries like agriculture and food processing, where avoiding chemical reactions or damage due to moisture is crucial.

The main advantages of this type of clamp are corrosion resistance, making them ideal for chemically aggressive or humid environments, easy installation due to their lightweight, and flexibility, which makes them suitable for a variety of diameters and materials.

Metal clamps

Metal clamps are designed to provide greater strength and resistance to high temperatures. They are commonly used in industrial applications where pipes must withstand high pressures or extreme operating conditions.

They have very high strength, making them perfect for high-pressure or high-temperature applications. They are built to last long in tough environments and have such structural stability that they ensure secure fixing even for large pipes.

To explore a complete range of pipe clamps, visit our dedicated page Pipe Clamps – LubeTeam Hydraulic.

Anti-vibration clamps

Anti-vibration clamps are designed to minimize vibrations and noise produced by fluid movement within pipes. These clamps often feature rubber inserts or similar materials to enhance insulation. They improve acoustic comfort in industrial environments and simultaneously protect pipes by reducing vibrations, preventing structural damage and wear. Thanks to their versatility, they are also suitable for a wide range of applications, from hydraulic systems to cooling circuits.

What factors should you consider when choosing clamps?

1- Pipe material

The material of the pipe is one of the main factors to consider when choosing a clamp. Plastic, steel, or copper pipes have different needs in terms of support and protection. For example, for plastic pipes, plastic or anti-vibration clamps are often preferable to avoid scratches or damage, while for steel or copper pipes, metal clamps offer greater stability and durability.

2- Diameter and operating pressure

The diameter of the pipe and the operating pressure directly influence the choice of the clamp. It is essential to select a clamp with compatible dimensions that can withstand the pressure exerted by the fluid inside the pipe. In particular, ensure that the clamp is designed to perfectly fit the pipe diameter, and consider the pressure, as metal clamps with high structural resistance are the best choice for high-pressure applications.

3- Usage environment

The environment where the system will be installed is another crucial aspect. In corrosive or humid environments, plastic or coated metal clamps are more suitable. In applications subject to vibrations, anti-vibration clamps are essential to ensure system safety and longevity.