Choosing the seals for a hydraulic cylinder is a decision that directly affects system stability, energy efficiency, and the overall lifespan of the equipment. Sealing is not an accessory but a structural component that defines the behavior of the cylinder both under extreme load conditions and during normal operation. A properly designed sealing system does not simply contain the fluid: it manages energy, controls friction, preserves mechanical components, and protects the circuit from contaminants that, over time, would undermine machine productivity.

The strategic function of seals in the hydraulic cylinder

A hydraulic cylinder contains different seals with specific functions, yet all contribute to the same purpose: ensuring that the pressure generated in the operating chamber is converted into useful force without energy loss. The rod seal prevents oil from leaking along its movement despite speed, vibrations, and pressure variations. The piston seal precisely separates the two chambers of the cylinder, transforming the pressure differential into linear motion. The wiper has a discreet but essential role: it cleans the rod from dust, mud, water, and abrasive particles every time it re-enters the barrel. Finally, the guiding rings keep piston and rod perfectly aligned, prevent undesired metal-to-metal contact, and preserve the integrity of the seals, which would otherwise rapidly fail under lateral loads.

These components work as a single organism. If even one fails, the cylinder loses precision, develops micro-leaks, increases internal friction, or—in the most severe cases—goes out of service. The reason why many seals fail prematurely is not the material itself, but an inadequate selection relative to actual operating conditions.

Seal materials: why the choice is never neutral

Operating conditions define the ideal sealing material. Each elastomer and thermoplastic has strengths, limitations, and specific responses to pressure, temperature, and fluid type. Nitrile, for example, is flexible, stable, and particularly suitable for mineral oils. It operates reliably as long as temperature remains moderate and the fluid does not contain aggressive additives. The hydrogenated version of nitrile extends this stability to more severe conditions, handling higher temperatures without hardening or micro-cracking.

Polyurethane is one of the most widely used choices in mobile and industrial applications requiring robustness. It resists abrasion, maintains shape even after thousands of cycles, and withstands high pressures without excessive deformation. It is especially suitable for dusty environments or those exposed to solid contaminants.

High-temperature applications or those involving synthetic fluids require advanced materials such as FKM (Viton), which maintains elasticity and chemical stability even when other elastomers degrade rapidly. When extremely smooth movements, reduced friction, or tolerance to very high temperatures are required, PTFE comes into play. Its almost “self-lubricating” behavior reduces start-up shocks and keeps sliding forces constant. However, it lacks natural elasticity and therefore requires an energizer—typically an internal O-ring that ensures the necessary pre-load for sealing.

The choice of material directly influences the operational life of the cylinder: an elastomer compatible with the oil and stable at temperature prevents swelling, hardening, exudation, and loss of resilience—phenomena that quickly lead to loss of efficiency.

The seal profile: the importance of geometry

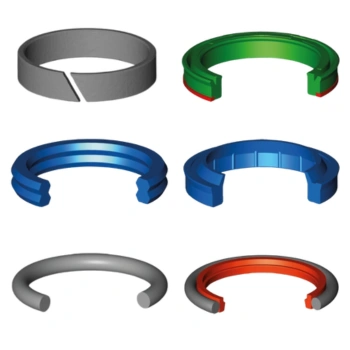

The material defines the chemistry of the seal, while the geometry determines its dynamic behavior. A U-cup, for example, uses internal pressure to increase the adhesion of its lip to the surface of the rod or piston. It provides a balance between sealing and sliding and is ideal for repeated cycles and smooth motion. A V-stack seal, on the other hand, works like a stack of rings that progressively expand with pressure. It is a robust solution suitable for high pressures and variable operating conditions, where sudden pressure spikes would endanger a simple lip seal.

O-rings remain a versatile solution for static applications, but in dynamic configurations they require backup rings to prevent extrusion. Extrusion is the most frequent cause of seal failure when pressure exceeds expected levels or when the radial clearance between piston/rod and barrel is too large. Once again, geometry, material, and operating context must be considered as parts of a single system.

Real operating parameters: what truly makes the difference

Seal selection must begin with real conditions, not just nominal ones. The maximum circuit pressure declared does not always match actual pressure. Hydraulic shocks, transients, and peaks generated by dynamic loads push materials beyond their safety window. When the cylinder operates at high speeds, the surface temperature of the rod increases, along with the risk of damage to the dynamic lip. A contaminated environment requires considering more aggressive wipers or more abrasion-resistant materials.

The type of fluid also plays a role. Modern biodegradable fluids, as well as high-performance synthetic oils, require specific materials that do not deteriorate chemically. Likewise, cylinders mounted on industrial machines subject to continuous cycles need seals capable of maintaining dimensional stability even after thousands of cycles, preventing compression set.

Mechanical alignment must also be evaluated. A misaligned cylinder, or one subjected to constant side loads, transfers stresses onto the seals that they are not designed to withstand. Guiding rings therefore become a structural element of the selection: they maintain linear movement and prevent piston and rod from twisting.

Proactive approach to maintenance and design

Predictive maintenance is the most effective strategy to preserve seal life. Continuous monitoring of leaks, oil analysis, observation of rod dynamic behavior, and temperature control make it possible to anticipate the moment of replacement. Acting before failure reduces downtime and keeps the entire system efficient.

Design, in turn, must include safety margins. The adoption of backup rings in high-pressure applications, the choice of materials compatible with the fluid, and the definition of mechanical clearances according to shared standards contribute to operational stability. Validating the sealing system during the commissioning phase allows verification of resistance to extreme loads and ensures that operating behavior meets design expectations.

Practical applications and selection criteria

In construction machinery operating under heavy loads and in the presence of abrasive dust, the most reliable solution combines polyurethane, V-stack profiles, and robust guiding rings. In an industrial high-temperature system where the fluid contains aggressive chemical additives, materials such as FKM or energized PTFE systems are preferred. In positioning systems or applications requiring extremely smooth motion, the choice falls on low-friction PTFE seals with elastomeric energizers, capable of ensuring precision and consistent response even after repeated cycles.

Selecting the sealing system for hydraulic cylinders requires a comprehensive engineering vision. Material, profile, fluid compatibility, working conditions, presence of contaminants, mechanical alignment, and maintenance strategy must be considered as integral parts of the same decision. When these elements combine coherently, the cylinder operates efficiently, without leaks, with consistent performance over time, and with a longer service life. It is precisely this integration of technical analysis, conscious choice, and proactive design that allows a company to increase the reliability of its systems and reduce operating costs—transforming a simple sealing component into a competitive advantage.