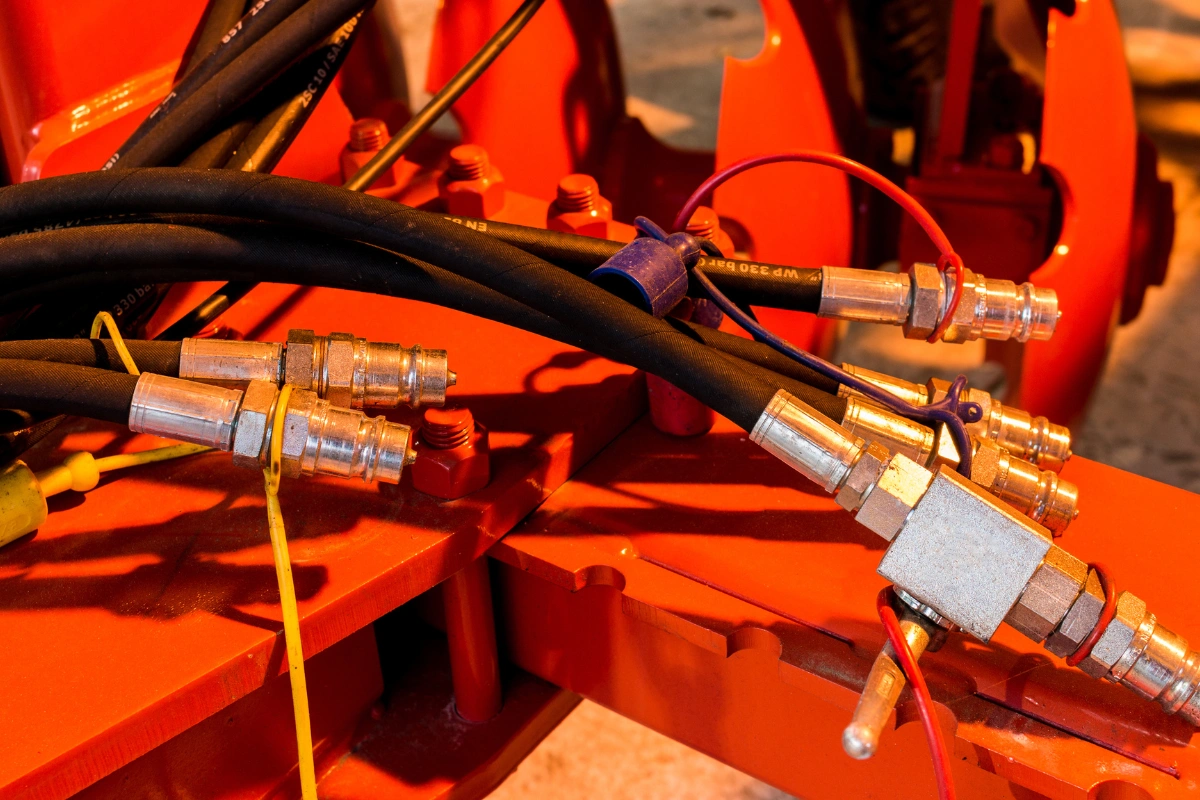

Properly sealing hydraulic fittings is essential to ensure the correct operation of any hydraulic system, as adequate sealing prevents leaks, increases efficiency, and prolongs the system’s lifespan. Here are various methods for how to seal hydraulic fittings, the materials used, and best practices to follow.

Why Sealing is Important

Sealing hydraulic fittings prevents hydraulic fluid leaks, which can cause not only efficiency loss but also equipment damage and safety risks. Inadequate sealing can also lead to pressure loss, reduced power, and system malfunctions.

For more information on different types of hydraulic fittings and their applications, visit our product page.

Sealing Methods

Sealing Tape

Also known as PTFE or Teflon tape, this is one of the most common methods for sealing threaded fittings. This tape is wrapped around the threads of the fitting to create a barrier that prevents fluid leaks.

How to apply it?

- Clean the threads of the fitting to remove dirt and debris.

- Wrap the sealing tape around the threads, following the direction of the threading.

- Ensure the tape covers all the threads, but avoid excessive buildup.

- Screw the fitting into place and tighten adequately.

Sealing tape is particularly effective for low and medium pressure applications. However, for high-pressure applications, liquid sealants are often preferred.

Liquid Sealants

Liquid or anaerobic sealants are another effective method for sealing hydraulic fittings. These products polymerize in the absence of air, creating a strong and high-pressure-resistant seal.

How to apply them?

- Thoroughly clean the threads of the fitting.

- Apply a small amount of liquid sealant to the threads.

- Immediately assemble the fittings and tighten according to the manufacturer’s specifications.

- Wait for the curing time indicated by the manufacturer before pressurizing the system.

Liquid sealants offer excellent chemical and mechanical resistance, making them ideal for critical industrial applications.

For more details on liquid sealants and their applications, you can visit https://www.engineeringtoolbox.com

Best Practices

Preparation of Fittings

Proper preparation of fittings is crucial for effective sealing. This includes cleaning the threads, inspecting for any damage, and choosing the appropriate sealant for the specific application.

Correct Tightening

Fittings should be tightened according to the manufacturer’s specifications. Over-tightening can damage the threads and compromise the seal, while under-tightening can cause leaks.

Monitoring and Maintenance

Even with proper sealing, it is important to regularly monitor the hydraulic system for any leaks. Preventive maintenance and timely replacement of worn components can prevent more serious and costly issues.

Using High-Quality Fittings

Using high-quality hydraulic fittings is essential for ensuring the system’s tightness and reliability. Superior quality fittings are designed to withstand high pressures and harsh operating conditions, reducing the risk of leaks and failures.

To explore a range of high-quality hydraulic fittings, visit our product page.