The productivity of a hydraulic system depends on a chain of components, but a crucial link, often underestimated, is the quick coupling. They do not only manage flow; they ensure operational safety, changeover time efficiency and circuit longevity. Selecting the wrong coupling is no minor mistake: it results in pressure drops, fluid contamination, unexpected downtime and, ultimately, a drastic reduction in ROI.

This ultimate technical guide provides engineers, production managers and maintenance technicians with a complete decision-making framework to move away from cost-based selection and adopt an approach based on long-term performance and reliability.

Understanding the Core of the Issue: Pressure, Flow and Fluids

Before evaluating geometries and materials, an engineer must ask three fundamental questions: What is the maximum operating pressure? What is the required nominal flow rate? Which fluid is circulating?

The Pressure–Impulse Relationship: Beyond the Static Value

A coupling must withstand not only the nominal static pressure, but above all the pressure spikes and hydraulic impulses generated by valves, pumps and aggressive duty cycles. Overlooking this aspect leads to material fatigue, deformation of internal components and, in the worst case, catastrophic failure. Choose a coupling with an adequate safety factor, bearing in mind that impulses can exceed the nominal value by up to 150%. A coupling designed with robust sealing and a solid locking mechanism absorbs these dynamic stresses more effectively, maintaining circuit integrity.

Flow Optimization: Avoiding Pressure Drop

Flow rate is directly linked to energy efficiency. An undersized coupling or one with a restrictive internal design creates excessive pressure drop, forcing the pump to work harder and generating unwanted heat. The coupling’s internal geometry (think about the shape and smoothness of the path) is critical. Flat-face models, for example, minimize turbulence and offer a more linear path compared to traditional ball-type designs, significantly reducing pressure losses and maximizing power transfer.

Chemical and Thermal Compatibility: Long Seal Life

Hydraulic fluid is not inert. Whether it is mineral oil, fire-resistant hydraulic fluids (HFA, HFB, HFC, HFD) or environmentally friendly fluids (HEES, HETG), their chemical composition interacts with seal materials (O-rings, sealing rings). The elastomer material must be selected according to the fluid and operating temperature. For example, NBR is common for standard mineral oils, but you may need FKM (Viton) for high temperatures or EPDM for phosphate ester-based fluids. An incompatible or overheated seal hardens, cracks and fails quickly, causing external leaks or, worse, air ingress into the system.

Technical Selection Criteria for Operational Excellence

Once the fluid-dynamic parameters are established, focus on the functionality and durability of the coupling in its specific operating environment.

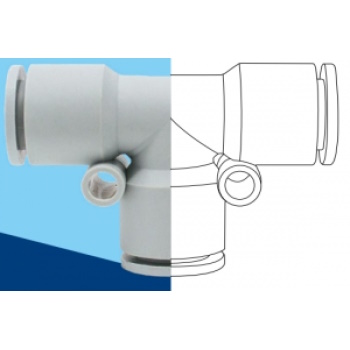

Design Geometries: Ball, Poppet or Flat Face?

Geometry choice is the most impactful decision on system performance:

- Ball/Poppet Couplings: These are the most widespread. They use a ball or poppet valve to close the fluid passage. They provide a good compromise between cost and performance, but the internal geometry can trap air during connection and they are more prone to dripping (leakage) upon disconnection.

- Flat Face Couplings: These represent the modern industrial standard for heavy-duty, contamination-sensitive applications. Their design minimizes air or dirt ingress into the circuit during connection and reduces fluid loss during disconnection to almost zero. They are essential in critical environments such as construction (excavators, skid steers) and agriculture, where the risk of contamination from dust and dirt is high.

LubeTeam recommends using flat-face Stucchi Quick Couplings (ISO 16028 certified) for systems requiring maximum cleanliness, safety and zero leakage.

Locking Mechanisms: Push-Pull vs. Threaded

The locking mechanism defines the speed and safety of tool changes:

- Push-Pull: These are the quickest, requiring only a push to connect. They are ideal for applications with high changeover frequency and moderate pressure, but they can disconnect under extreme vibration or side loads.

- Threaded: Connection is made by screwing a nut. They provide unmatched anti-disconnection safety and are the mandatory choice for very high-pressure applications or where violent spikes and continuous vibrations are present. The trade-off is a slightly longer changeover time, but the operational peace of mind more than repays the investment. Choose threaded couplings for applications with hydraulic hammers, milling heads or heavy lifting systems.

Surface Treatments: Environmental Resistance

The working environment determines the need for corrosion protection. Standard zinc-plated steel is not sufficient for saline environments, marine (offshore) applications or where aggressive chemicals are present. For such conditions, consider:

- Stainless Steel (AISI 316): Offers excellent resistance to corrosion and extreme temperatures but comes with a higher initial cost.

- Special Surface Treatments (e.g. Zinc-Nickel): These treatments provide salt spray resistance up to 1000 hours or more, far exceeding traditional zinc plating performance. They offer an excellent cost–life ratio for machines operating outdoors in harsh conditions (agriculture, earthmoving).

Anti-Contamination Strategies and Proactive Maintenance

Contamination is the main cause of hydraulic system failure. As the interface point with the outside, quick couplings play a crucial role in prevention.

Contamination Control: Protective Caps and Covers

When a coupling is disconnected, its open face exposes the system to solid particles, moisture and air. A competent maintenance technician does not rely on the coupling alone but always uses protective caps and covers. This simple, often overlooked accessory prevents dirt accumulation on sealing surfaces and reduces the likelihood that contaminants will be pushed into the circuit upon reconnection. Implement a strict policy on the use of these accessories as a standard procedure.

Residual Pressure Management (Depressurization)

Connecting two circuits with different residual pressures is often an impossible or dangerous task. Many systems, once switched off, retain trapped pressure due to thermal expansion or the action of check valves. Attempting to connect a coupling under pressure not only damages seals and the locking mechanism but also creates a serious risk for the operator.

The most elegant solution is the use of couplings with integrated depressurization valve or push-button depressurization tips. These devices allow the operator to safely vent residual pressure before connection, drastically reducing the effort required and preserving component integrity. In the absence of a dedicated coupling, integrate relief valves upstream of the connection point.

Inspection and Replacement: Predictive Maintenance

The service life of a quick coupling is limited by the number of connection/disconnection cycles and environmental conditions. Do not wait for evident dripping or complete blockage. Integrate periodic inspections that include:

- Verification of Axial/Radial Play: Excessive play may indicate wear of the locking mechanism.

- Visual Inspection of Seals: Look for signs of hardening, cutting or crushing. A seal that has lost its elasticity is an imminent failure.

- Low-Pressure Functional Test: Perform a quick visual test under initial operating conditions to detect minor leaks that will soon worsen.

Always replace male and female couplings together. Matching a new component with a worn one accelerates deterioration of the new element, cancelling out the benefit of partial replacement.

The Competitive Advantage of the Right Choice

Selecting quick couplings is not a purchasing detail but an engineering decision that directly affects total operating costs (TCO). A higher-quality, correctly sized coupling does not cost; it saves. It reduces downtime for maintenance, eliminates fluid loss and, most importantly, protects the heart of the system from damage caused by contamination. By implementing the technical criteria described, the company ensures that every operating cycle is safer, more efficient and more predictable. Investing in high-quality quick couplings means investing in uptime and system reliability.