In the hydraulic world, temperature control is not a detail. It is a condition for the system’s survival. Oil that constantly operates above its ideal thermal range loses viscosity, oxidizes more quickly, and drastically reduces the service life of pumps, valves, and seals.

The choice of the heat exchanger, therefore, is not a catalog item: it is a design decision that affects reliability, maintenance costs, and production continuity.

Among the most widespread solutions, two technologies stand out: plate heat exchangers and shell-and-tube heat exchangers. Both perform the same task, but they do so in radically different ways.

Understanding when one is better than the other means avoiding unnecessary oversizing or, worse, ineffective cooling systems.

The real problem: why oil overheats

Every hydraulic system generates heat. Internal friction, volumetric losses, throttling across valves, and variable loads transform mechanical energy into heat.

The problem arises when the heat produced exceeds what is naturally dissipated.

Direct effects of overheating

- Reduction in viscosity → greater internal losses

- Accelerated oil oxidation → sludge and deposits

- Premature aging of seals

- Decrease in overall system efficiency

At this point, the heat exchanger comes into play, with a single goal: removing heat from the oil in the most efficient and controlled way possible.

The role of the heat exchanger in the hydraulic system

An effective heat exchanger works quietly, steadily, and predictably. It must not create excessive pressure drops, must not foul easily, and must maintain performance over time.

This is where the real technical comparison begins: plates or shell-and-tube?

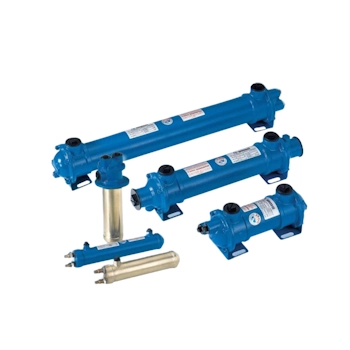

Shell-and-tube heat exchangers: characteristics and limits

Shell-and-tube heat exchangers represent the traditional solution for water-oil cooling. The logic is simple: oil flows around a bundle of tubes, while water flows inside them.

When we talk about this technology, we are referring to Emmegi water-oil heat exchangers.

Strengths of shell-and-tube exchangers

- Robust and proven construction

- Good tolerance to dirty fluids

- Resistance to high pressures

Technical limitations to consider

- Large footprint

- Lower thermal efficiency for the same volume

- Less effective use of heat transfer surface

- More complex cleaning

- Limited fine modulation of performance

Shell-and-tube exchangers work well when space is not an issue, the water is not particularly clean, and thermal load variations are limited.

Plate heat exchangers: how they really work

Plate heat exchangers use a series of corrugated metal plates assembled together. Oil and water flow through alternating channels, physically separated but in close thermal contact.

When discussing this technology, the correct reference is Emmegi plate heat exchangers.

Why plates transfer more heat

The corrugations of the plates create micro-turbulence. This effect breaks the fluid boundary layer and dramatically increases heat transfer.

In practice, it’s like constantly stirring the fluid while cooling it, instead of letting it flow “flat.”

When plate heat exchangers are better than shell-and-tube

1. When space is limited

A plate heat exchanger can provide the same thermal capacity as a shell-and-tube exchanger while occupying up to 50% less space.

In modern industrial systems, where hydraulic units are increasingly compact, this factor is often decisive.

2. When high thermal efficiency is required

Under the same operating conditions, a plate heat exchanger transfers more heat. This means:

- More stable oil temperature

- Lower required water flow rate

- Better thermal control even with variable loads

If the system operates intermittently or with load peaks, plates respond more quickly.

3. When temperature control is critical

In applications where a few degrees make the difference (presses, machine tools, automated lines), precision in heat exchange is essential.

Plates allow finer regulation because they react more quickly to changes in flow and temperature.

4. When reducing energy consumption is a goal

Higher thermal efficiency means less water to cool and less energy spent upstream.

In the medium term, a properly sized plate heat exchanger reduces operating costs.

5. When maintenance must be fast and schedulable

Plate heat exchangers are modular. This allows:

- Quick disassembly

- Immediate visual inspection

- Easier chemical or mechanical cleaning

From a predictive maintenance perspective, this becomes a competitive advantage.

When shell-and-tube remains the right choice

Saying that plates are always better would be technically incorrect.

Shell-and-tube exchangers remain preferable when:

- The cooling water is very dirty

- Operating pressures are extremely high

- Space is not a constraint

- The system operates continuously and steadily

In these cases, the structural robustness of shell-and-tube exchangers still plays a key role.

Do not make these mistakes when choosing a heat exchanger

Oversizing “for safety”

An oversized heat exchanger performs poorly, costs more, and can create thermal stability issues.

A precise sizing based on real data is always better.

Ignoring oil viscosity

Cold oil is denser and flows with more difficulty. Plates, thanks to turbulence, handle these conditions better than shell-and-tube exchangers.

Neglecting the real condition of the water

Water quality directly affects the choice. This factor must always be analyzed beforehand.

Plate heat exchangers are the best choice when efficiency, compactness, and precise temperature control are required.

In modern hydraulic systems, characterized by variable loads and limited space, they often represent the most intelligent technical and economic solution.

Shell-and-tube exchangers remain a valid technology in specific contexts, but they are no longer a universal answer.

The real difference is always made by a conscious choice, based on real data rather than design habits.