Metal electromagnetic level sensor gauges use the force of a magnet in the float to change the electrical status of a reed switch.

Metal electromagnetic level sensor gauges use the force of a magnet in the float to change the electrical status of a reed switch.

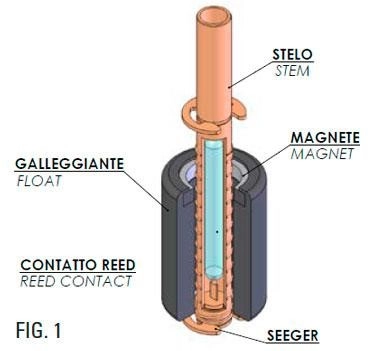

FIG. 1 shows the components of an metal electromagnetic level sensor gauge that operates vertically.

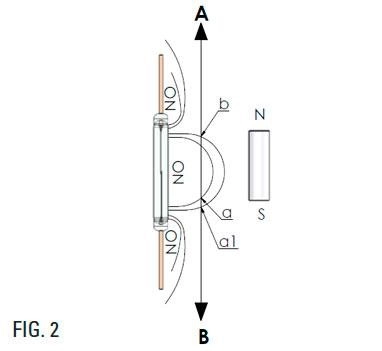

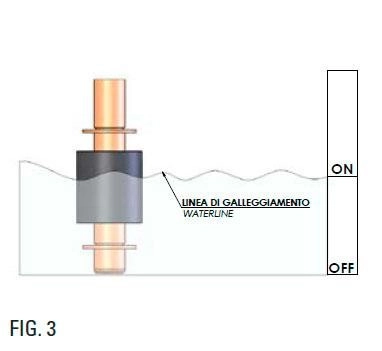

Figures 2 and 3 show an indicator with a normally-open contact. When the level of fluid increases, the float moves from B towards A. As soon as the magnet in the float reaches point A, the contact closes. The movement of the float is normally limited by a mechanical stop. If there is no stop, the contact returns to its original position when the magnet passes point B. When the level of fluid drops, the float moves from A towards B, and as soon as the magnet reaches point A1 the contact opens.The difference between points A and A1 is called the differential, or hysteresis, of the contact.

This differential is normally very small, but it can be increased if necessary using special contacts. To switch a contact from NO to NC or vice versa, it is usually enough to invert the float.