In the pulp and paper industry, effective management of contamination in fluid systems is a fundamental challenge that directly impacts product quality and equipment reliability.

Machinery and equipment used in this sector operate under specific oil cleanliness conditions but must constantly face the risk of contamination. Addressing this issue requires innovative and targeted solutions to ensure proper equipment functioning and to guarantee the quality of the final product.

Solutions by Pall Corporation

To meet this challenge, it is essential to employ advanced filtration technologies capable of consistently controlling contamination levels throughout the entire process. Pall Corporation offers a complete range of filtration and separation technologies designed specifically to meet the rigorous requirements of the pulp and paper industry.

Athalon™ Filtration Technology

One of the solutions offered by Pall is the Athalon™ filtration technology, stress-resistant and designed for particulate filtration. This system removes particulate contamination from the environment, protecting critical machine components and reducing friction wear that could compromise process reliability.

Separation Systems for Water, Condensate, and Trapped Gases

Additionally, Pall’s water, condensate, and trapped gas separation systems are capable of effectively removing water and entrained gases, ensuring clean process fluids free of contaminants that could affect equipment performance.

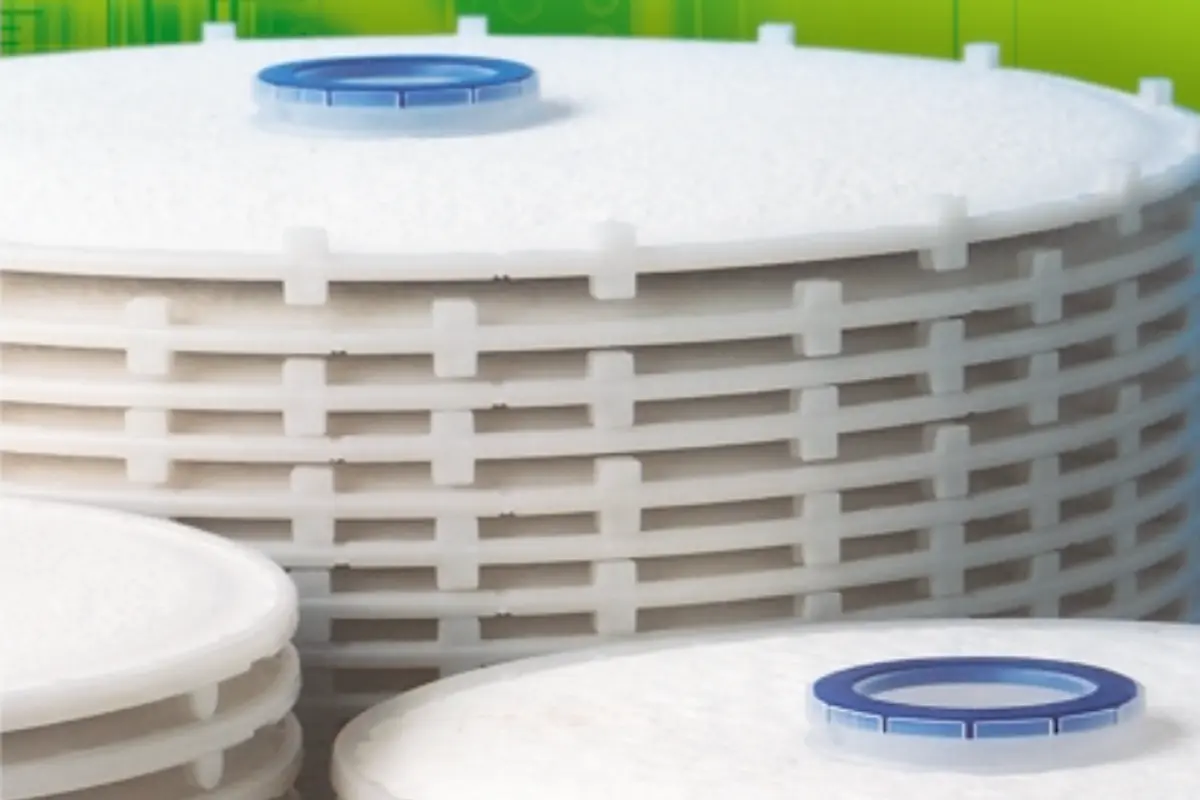

SUPRAdisc™ Varnish Separation Technology

Finally, the SUPRAdisc™ varnish separation technology is designed to remove varnishes, gels, colloids, and fine particles resulting from extreme temperatures and thermal processes. This helps maintain efficient and reliable hydraulic and lubrication systems, preventing critical component deterioration and extending equipment service life.

SUPRAdisc™ filter modules feature an innovative design that incorporates a dual separator concept, where the filter media and separators are stacked on a central core and compressed to produce a stable, high-strength unit. Each filter sheet is individually sealed and separated, resulting in an effective filtration area close to 100%, dimensionally stable during shipping, handling, filtration, and maintenance.

In addition to removing varnish, the SUPRAdisc™ filter module is capable of:

- Improving fluid filtration properties

- Removing gels and colloids

- Removing free water (in small quantities)

- Retaining fine contaminants at high loading rates.

The use of these innovative filtration technologies developed by Pall Corporation significantly contributes to the protection of equipment and the quality of final products in the pulp and paper industry.