Choosing the right oil for hydraulic pistons is crucial to ensuring the proper functioning of the hydraulic system. Hydraulic oil not only lubricates moving parts but also allows the transmission of force through the system, maintaining constant pressure and reducing wear on components. Using inappropriate oil can lead to breakdowns, malfunctions, and accelerated wear of parts.

Let’s find out what oil to use for hydraulic pistons.

Main properties of hydraulic oil

Hydraulic oils must meet specific technical characteristics to ensure proper performance. The most important properties include:

- Viscosity: It is essential to choose oil with the correct viscosity, which is the resistance to flow. Oils with too high viscosity can create resistance, while those with too low viscosity may not provide adequate lubrication.

- Thermal stability: Hydraulic oil must be able to maintain its properties even at high temperatures, without degrading or causing deposits that could damage the system.

- Oxidation resistance: The oil’s ability to resist oxidation is essential to prolong its life and prevent the formation of sludge or acids that could damage hydraulic components.

When to use different types of hydraulic oil?

Mineral oil

Mineral oils are among the most commonly used in hydraulic systems due to their versatility and reliable performance. They are derived from petroleum refining and are available in various viscosity grades, making them suitable for a wide range of applications.

This type is ideal for many industrial and mobile systems and is commonly used in agricultural machinery, construction equipment, and systems operating at moderate temperatures. However, in extremely hot or cold environments, other options may need to be considered.

Synthetic oil

Synthetic oil offers superior performance compared to mineral oils, particularly in terms of resistance to extreme temperatures and durability. It is produced through chemical processes that allow the creation of hydraulic fluid with specific characteristics.

This oil is recommended for applications where hydraulic systems are exposed to high or very low temperatures or where greater wear and oxidation resistance is required. It is often used in high-performance industrial systems and harsh environments where fluid longevity is a priority.

Biodegradable oil

In recent years, environmental concerns have led to the development of biodegradable hydraulic oils. These fluids are made from vegetable or synthetic bases and naturally decompose in the environment without causing pollution.

Biodegradable oils are ideal for applications where there is a risk of leaks or spills in the environment, such as machinery used in natural parks, forests, or near waterways. They offer an excellent alternative to traditional oils, reducing environmental impact without compromising performance.

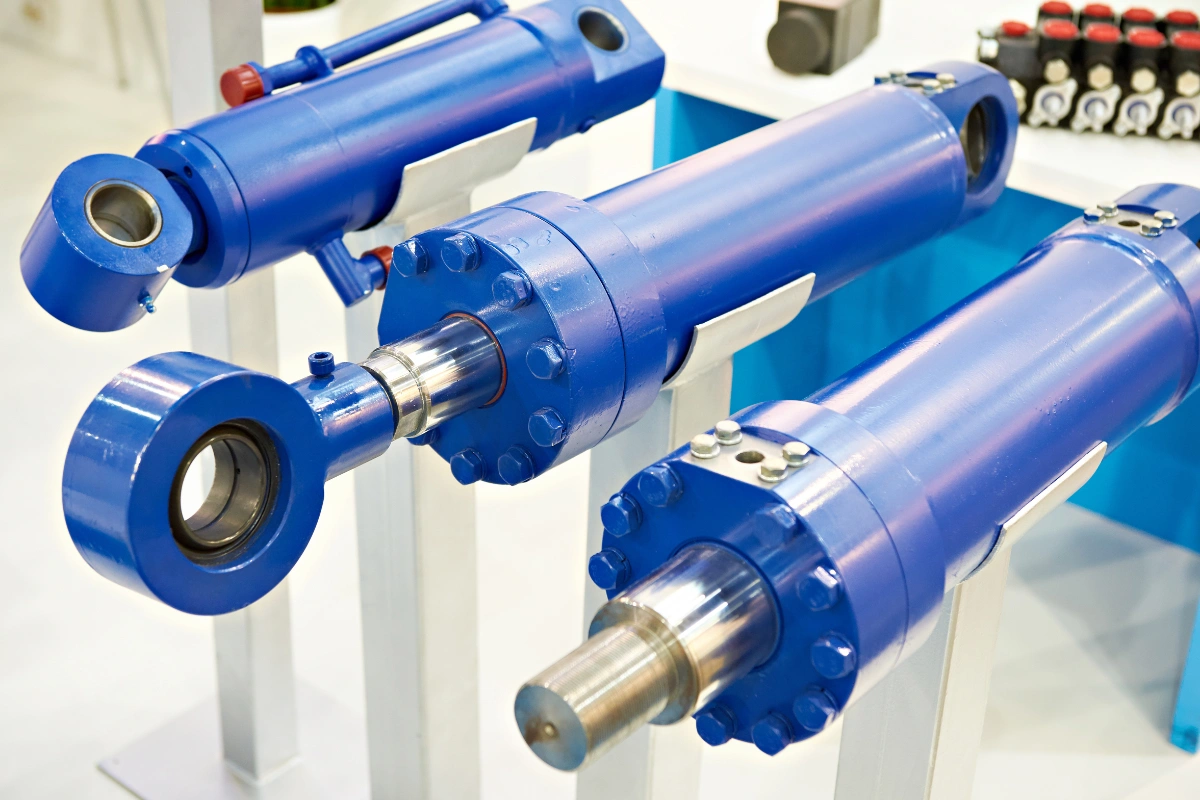

For more details on hydraulic cylinders and their maintenance, visit our page dedicated to Hydraulic Cylinders.

Practical tips for choosing hydraulic oil

Verify

Before selecting hydraulic oil for pistons, it is important to consult the recommendations of the equipment manufacturer. The technical specifications in the product manual provide precise indications of which type of oil to use, including viscosity and other technical characteristics.

Temperature control

The operating temperature of the system is a crucial factor in choosing hydraulic oil. If the system operates in high-temperature environments, synthetic oil may be more suitable. Conversely, if it is exposed to extremely low temperatures, it is important to opt for oil that retains its lubricating properties even in cold conditions.

Maintenance and monitoring

Regularly checking the level and condition of hydraulic oil is essential to prevent problems. Degraded or contaminated fluid can compromise the performance of pistons and the entire system.