The HTP070 purifier permits treatment of the oil in a power transformer, while on-line and on-load.

This product is available for rental. Contact us!

The HTP070 purifier permits treatment of the oil in a power transformer, while on-line and on-load.

water content at 20°C………………………………………….. < 10 ppm

Particle count according to ISO 4406……………… < 12/10

Particle count according to NAS 1638……………. < 4

Dielectric strength…………………………………………………….. > 75 kV

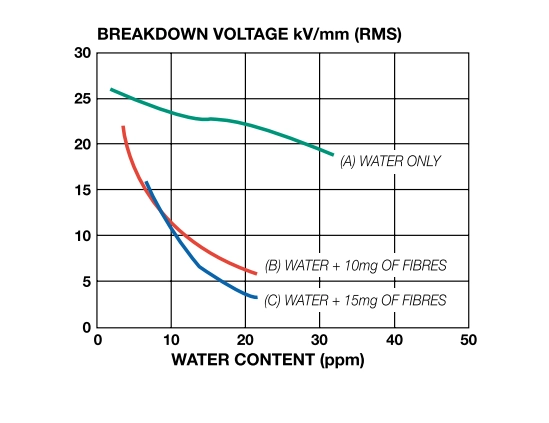

It is absolutely essential to keep the overall contamination level of the transformer oil in service at low levels to ensure the dielectric strength of the oil and to minimise the risk of transformer breakdown.

The table above shows typical values for a new transformer.

They must be adapted to suit the type of transformer, its age, and technology.

A new method of treating transformers while on-load has been developed by Pall and EDF, working in partnership and departing from conventional technology.

This process is the subject of an agreement between Pall and EDF which covers the treatment of power transformers under load using the HTP070 purifier, a specially designed unit for this application.

The HTP070 purifier permits extremely high

performances to be reached, without manual supervision except during connecting and disconnecting operations.

The development of this type of treatment offers the following advantages:

The process allows treatments lasting several weeks and can therefore be much more efficient. Since such treatments do not require the transformer to be taken out of service, a major cost factor has been eliminated.

Remote monitoring package:

The HTP 070 can be equipped with a remote monitoring package. The system involves the use of a Global Satellite Modem (GSM) or landline connected to the purifier PLC together with all necessary pressure transducers and moisture sensors.

This allows the operator:

This option has proved its value as the HTP 070 has to operate in remote ares for long periods.

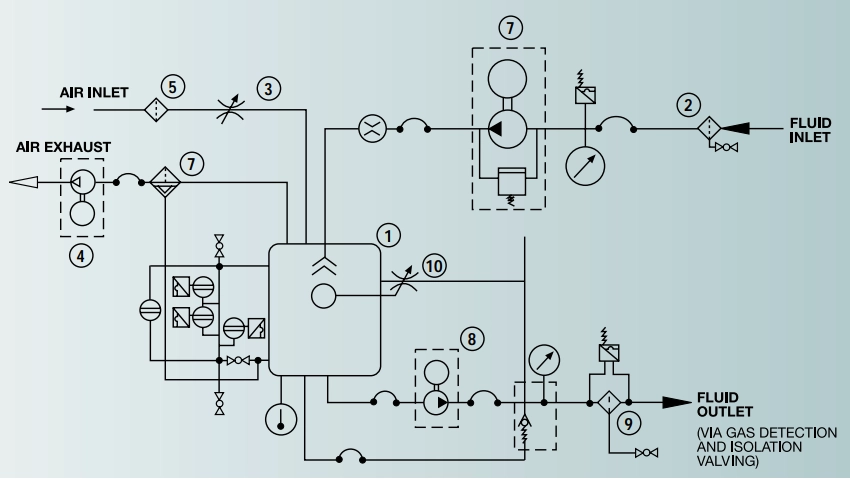

The fluid is pumped into the vacuum chamber (1) through the inlet strainer (2) by the inlet pump (7).

A spray nozzle at the top of the chamber produces a cone of fluid with a thin film and a large surface area.

The vacuum chamber is maintained at approximately 10 mbar absolute by the vacuum pump (4). Air entering the chamber passes through an air breather (5), removing airborne contamination to avoid adding dirt to the system. The air

expands rapidly through a restriction (3) to approximately 100 times its ambient volume which decreases the relative humidity inside the chamber to a fraction of the ambient level.

Gases and water vapour are transferred from the fluid surface to the upward flowing air thereby drying and degassing the fluid. The wet air is then exhausted via the oil mist separator (7) and vacuum pump (4) to atmosphere.

The purified fluid collects at the bottom of the chamber and is returned to the transformer or reservoir via the discharge pump (8) through the ß5(c)≥1000 high Beta performance ‘Ultipor III’ filter element (9). When the discharge filter element reaches the pre-set differential pressure a warning beacon is illuminated.

The fluid level in the vacuum chamber is maintained by a level sensor (10) which allows some of the fluid to circulate back to the chamber.

A sight glass is fitted to give visual confirmation of the fluid level in the chamber. Downstream of the discharge filter (9) is a second vessel and associated valving (not shown) for the detection and removal of air bubbles in the transformer oil.

This product is available for rental.

Our exclusive rental service allows our customers to use equipment from the most prestigious brands in the industry. With a wide catalog of high-quality instrumentation, we guarantee cutting-edge solutions for various needs.